Innovation in thin-walled cannula demonstrated by Accumold at MD&M East event

In the rapidly evolving world of medical technology, advancements in micro moulding are making significant strides, particularly in the production of miniaturized components crucial for modern healthcare applications.

One of the latest breakthroughs comes from the use of specialized micro injection molding machines, such as the MHS M3, which employs patented ISOKOR® technology and a direct-gating hot runner system. This technology allows for the production of micro parts weighing as little as 10 milligrams with micron-level tolerances, eliminating cold runners and significantly reducing waste, cycle times, and improving material utilization while maintaining high consistency and scalability.

Material innovations also play a pivotal role, with medical-grade polymers like PEEK (polyether ether ketone) being prominent due to their biocompatibility and strength, especially for implantable devices. Thermoplastic elastomers (TPEs) and polypropylene are being used to enhance device functionality, from soft grips to cost-effective disposables.

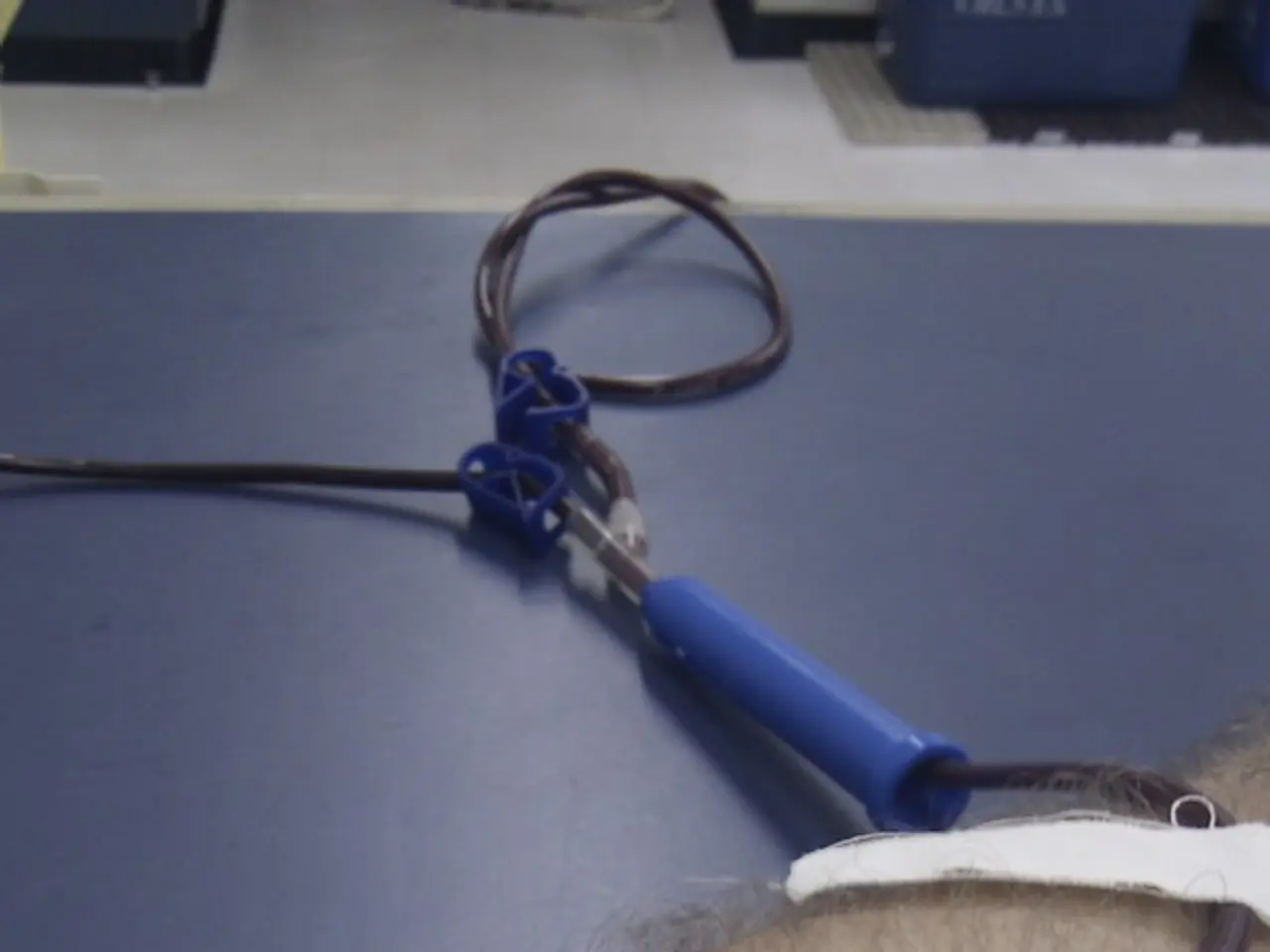

Accumold, a company with over 40 years of experience in producing complex micro components with tolerances down to a few microns, has recently achieved a milestone in thin-walled cannula production, now possible through a single moulding process. This technique allows for wall thicknesses as low as 0.1 mm, supporting volumes of up to 40 million parts per year per cell.

The focus on speed, consistency, and reliability is crucial in healthcare manufacturing, according to Brett Saddoris, Technical Sales Manager at Accumold. These qualities are exemplified in the company's expertise, which extends beyond thin-walled cannulas to various medical applications, including surgical tools, diagnostic kits, and drug delivery systems.

The new process has improved part quality and production efficiency, reducing variability and opening up new design possibilities. This development is particularly valuable in the development of minimally invasive and wearable medical devices, a sector that is expected to witness rapid growth, projected to grow from $596.7 million in 2024 to $1.66 billion by 2033 at a CAGR of 12.2%.

At MD&M East 2025 in New York City from May 20-22, Accumold will showcase its latest innovations in micro moulding for medical devices. Attendees can visit Booth 551 to meet the technical team, view micro moulded samples, and discuss how micro moulding for medical devices can accelerate development and reduce time to market.

The role of micromoulding in wearable diabetes devices, as well as its impact on process automation and validation to meet regulatory and quality standards, are topics that have been extensively covered in articles such as "The role of micromoulding in wearable diabetes devices" in "Medical Plastics Insights" and "Navigating the complexities of micro moulding for medical devices" in "Medical Device Manufacturing Insights".

In summary, current innovations and trends in advanced micro moulding for medical devices include the use of breakthrough micro injection molding machines, the adoption of advanced biocompatible materials, the manufacturing of complex, multi-component micro features, an emphasis on process automation and validation, and increasing market growth fueled by healthcare trends requiring miniaturized, high-quality parts.

- In the expanding healthcare manufacturing industry, advancements in micro moulding, such as the use of specialized micro injection molding machines, are revolutionizing the production of medical devices, especially those requiring miniaturized components.

- The industry is benefiting from material innovations, with medical-grade polymers like PEEK and TPEs being utilized for their biocompatibility, strength, and device functionality improvements.

- The use of micro moulding technology has led to significant improvements in production efficiency and part quality, which is crucial for the development of minimally invasive and wearable medical devices, a sector anticipated to experience substantial growth.

- The focus on speed, consistency, and reliability, as exemplified by companies like Accumold, extends to various medical applications, including surgical tools, diagnostic kits, and drug delivery systems.

- The role of micro moulding in the development of wearable diabetes devices and its impact on process automation and validation to meet regulatory and quality standards are topics of interest and have been extensively covered in articles such as "The role of micromoulding in wearable diabetes devices" and "Navigating the complexities of micro moulding for medical devices."