Innovations in AI for Prosthetics and Rehabilitation

Artificial Intelligence's Influence and Impact on Engineering Prosthetic Limbs

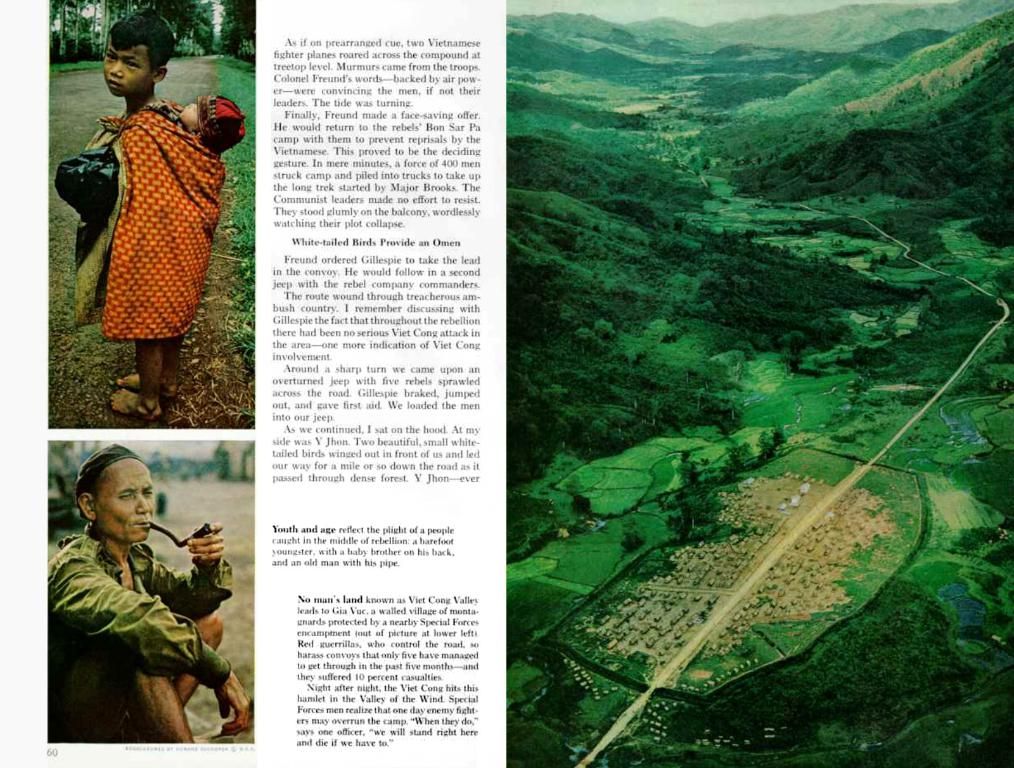

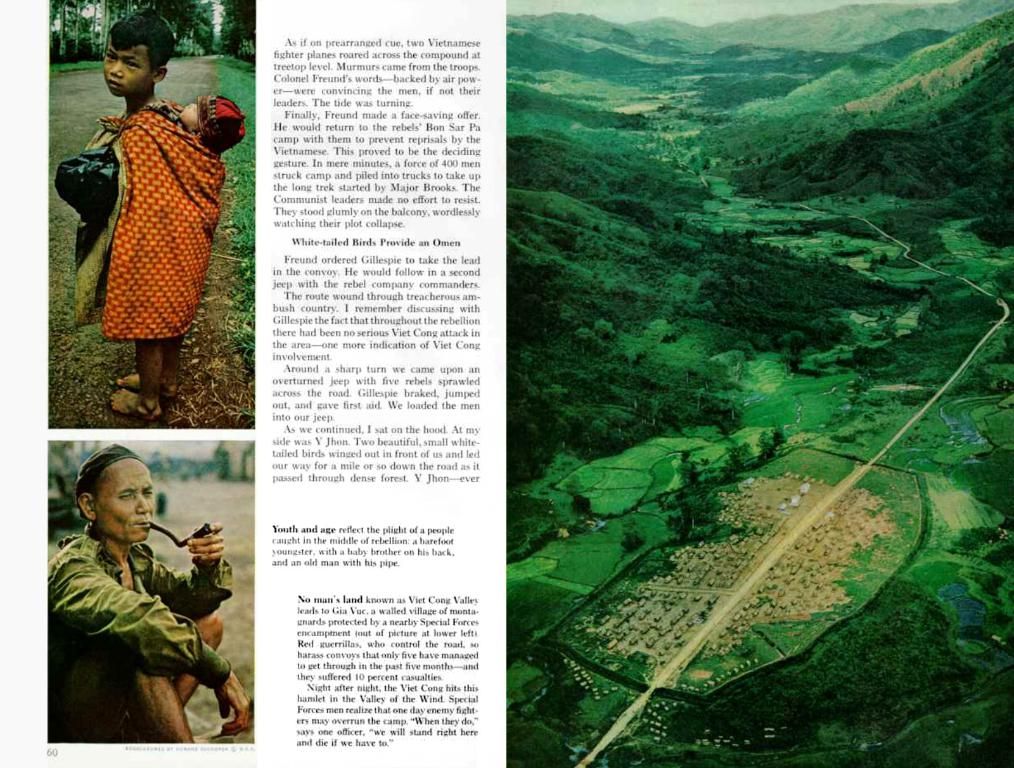

In the realm of biomechanics, artificial intelligence (AI) has emerged as a game-changer in the design and manufacture of prosthetics. Leading rehabilitation aid manufacturers utilize AI's potential to simulate various anatomical and biomechanical functions, offering life-changing solutions for people with disabilities.

The New Era of Prosthetics

Prosthetics can be any artificial body part replacing a missing one due to injury, disease, or congenital conditions. Today, innovations in AI and materials—from titanium to carbon fibers—have led to cutting-edge, highly functional prosthetics. The process of creating these devices is similar to making medical insoles: using digital scans of the amputated limb to design a matching socket and using electrodes to translate muscle signals into controlled movements.

Redefining Prosthetic and Orthotic Engineering

The fields of prosthetics and orthotics have traditionally relied on manual measurements, mechanical adjustments, and trial-and-error methods. However, the integration of AI has revolutionized these sectors by incorporating machine learning, robotics, and sensing technology. This transformation has resulted in dynamic systems, as opposed to static devices, that can learn, adapt, and evolve to meet the unique needs of individual users.

A Brief History of AI in Prosthetics and Orthotics

The first intelligent prosthetic limb, the Intelligent Prosthesis Plus, was developed by Charles A. Blatchford & Sons, Ltd in 1993. Since then, advancements like the C-leg released by Ottobock in 1997, the world's first fully integrated limb, Linx, introduced by Blatchford in 2015, and the i-limb ultra revolution hand by Touch Bionics have reshaped the entire industry. Researchers are also working on implementing brain-computer interfaces for more natural, real-time functionality.

The Role of AI in Improving Prosthetic Design

Artificial intelligence is revolutionizing prosthetic design and rehabilitation in several ways:

- Adaptive Prosthetics: AI-powered prosthetics can adapt to user movements and environmental changes.

- Dynamic Adjustment: AI-driven prosthetic legs adjust gait and force distribution dynamically when transitioning from flat surfaces to stairs or uneven terrain.

- Customized Design: AI-enhanced technology leverages imaging data and user feedback to create prosthetics that offer optimal fit and improved function.

- Generative Design Tools: These tools create prosthetic sockets that precisely fit individual anatomy, enhancing comfort and reducing pressure points.

- Neural Integration: AI-based brain-machine interfaces allow users to control prosthetics via neural signals.

- Neural Signal Interpretation: AI interprets brain activity to execute precise movements in prosthetics, providing users with greater autonomy.

- Predictive Maintenance: AI technology tracks device usage to predict wear and tear, ensuring timely maintenance and longer lifespan.

- Smart Orthotic Braces: Equipped with sensors, these braces alert users to potential issues before failures occur.

- Biomechanical Simulation: AI simulates human movement to optimize prosthetic and orthotic designs before production.

- Digital Assessment: Digital tools evaluate balance, alignment, and weight distribution, allowing for precise adjustments during design.

The integration of AI and biomechanics will continue to transform the world of prosthetics, offering more responsive, intuitive, and integrated solutions. Now, let's delve into the role of our website, Center, in fostering these advancements.

Our mission at Center is to drive progress in the medical engineering sector through specialized courses and high-quality healthcare solutions, enabling people with disabilities to achieve greater independence and improved quality of life.

Resources:

- Aminian, K., Khoshaloo, M., Shafiee, M. A., & Sharifi, M. (2020). Prosthetic control: Walking and running at different speeds. "IEEE Transactions on Neural Systems and Rehabilitation Engineering," 28(1), 104-114.

- Knosche, A. (2018). Integrating biomedical sensors in prosthetic limbs: Overview, challenges, and perspectives. "IEEE Transactions on Neural Systems and Rehabilitation Engineering," 26(7), 1311-1319.

- Reed, P. M., Van der Smagt, P., & Ajoudani, H. (2019). 3D printing and novel materials in the production of prosthetic devices. "Prosthetics and Orthotics International," 43(4), 321-330.

- In the field of biomechanics, artificial intelligence is transforming the design and production of prosthetics, offering life-changing solutions for individuals with disabilities.

- Prosthetics, which are artificial body parts replacement for missing limbs due to injury, disease, or congenital conditions, are being revolutionized by innovations in AI and materials like titanium and carbon fibers.

- AI integration in prosthetics and orthotics sectors has been instrumental in introducing machine learning, robotics, and sensing technology, leading to dynamic systems that learn, adapt, and evolve.

- The Intelligent Prosthesis Plus developed by Charles A. Blatchford & Sons, Ltd in 1993 was one of the earliest examples of AI-powered prosthetics.

- The C-leg from Ottobock, the first fully integrated limb, and the i-limb ultra revolution hand by Touch Bionics are examples of significant advancements in the prosthetics industry.

- AI has the potential to improve prosthetic design in multiple ways, such as making prosthetics adaptive, offering dynamic adjustment, customized design, generative design tools, neural integration, and neural signal interpretation.

- AI technology can predict wear and tear, ensuring timely maintenance and prolonging the lifespan of prosthetics.

- Smart orthotic braces equipped with sensors can alert users to potential issues before failures occur, enhancing overall safety and user experience.

- AI simulates human movement to optimize prosthetic and orthotic designs, helping create more efficient and effective devices.

- Digital assessment tools can evaluate balance, alignment, and weight distribution, allowing for precise adjustments during design.

- Our website, Center, strives to promote advancements in the medical engineering sector, enabling people with disabilities to achieve greater independence and improved quality of life through specialized courses and healthcare solutions.